MANUFACTURING

DOMESTIC & OVERSEAS CAPABILITIES

LIGHT FIXTURE MANUFACTURING

DOMESTIC & OVERSEAS CAPABILITIES

MANUFACTURED IN THE USA

Our 30,000 square foot factory in Bronx, New York is vertically integrated with state-of-the-art, automated and hand-operated machinery. Our team of engineers, crafts-people and artisans are highly skilled in 3D CAD drawing, concept sketching, laser cutting, CNC machining, welding, polishing, hand- and – spray finishing.

OFF-SHORE MANUFACTURING

Our team in New York works seamlessly with our overseas team to provide cost-effective solutions for guest room and corridor lighting. We have a long-term partnership with a factory in China, where our team controls 100% of the inspection process to ensure all fixtures adhere to our high-quality standards.

ENGINEERING

Our in-house engineering team has skill sets ranging from initial concept sketching, AutoCAD, 3D modeling, shop-drawing production, and interpreting designer concepts into CAD produced shop drawings for manufacturing.

In-house engineers interpret design concepts into manufacturable products.

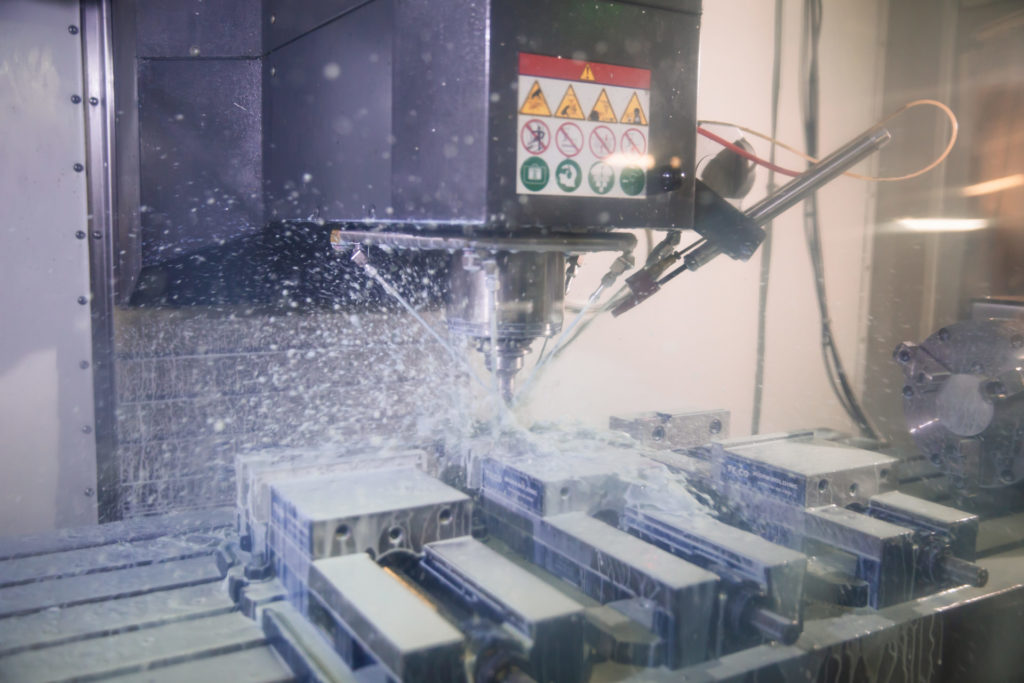

CNC MACHINING

We use modern technology and a state-of-the-art CNC lathe and milling machine to produce metal parts with precision.

CNC lathe and milling machine to produce a variety of metal parts.

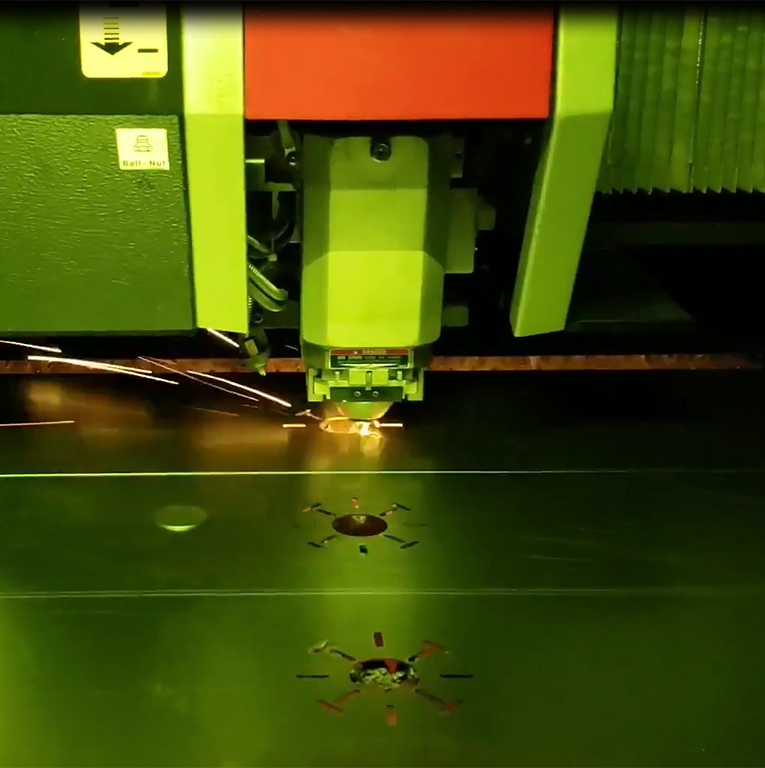

METAL CUTTING

Our large-scale metal cutting laser machine can cut large sheets of metal into patterns and shapes, for fixtures and to create templates.

Metal cutting laser machine can cut large sheets of metal into various shapes and patterns.

WELDING

Our certified welders know the art of heating and shaping materials. They have strong technical educations and specialize in fabricating and fusing together materials like brass, steel, stainless steel and aluminum.

Fabricating and fusing together various metals and materials.

POLISHING

We have various polishing machines, hand and automated, for polishing large- and small-scale metalwork.

Capabilities to polish any size piece of metal.

HAND FINISHES

Our in-house artisans are true artists; skilled to apply finishes using multiple finishing techniques. Faux finishes painted by hand to resemble real alabaster, marble or wood.

True artists skilled at applying faux finishes by hand.

SPRAY BOOTH

Our factory houses a state-of-the-art, automobile-scale spray booth for spraying and finishing large-scale fixtures and parts.

State-of-the-art spray booth.

SANDBLASTING

Metal parts are sandblasted to ensure a smooth surface prior to applying painted finishes. Glass and acrylic are sandblasted to create etched and frosted patterns.

Sandblasting to smooth surfaces and create frosted glass and acrylic.

MACHINING

Our factory is vertically integrated with various machines that enhance our capabilities to meet the most challenging designs. Lathe, milling, rolling, drilling, and grinding machines, to name a few.

CUSTOM SHADES

Select from our wide range of standard shade materials or specify your own. We can make custom wire forms of any shape or size.

On-site shade department. Select from our standard materials or specify your own.

quality control

Every item is thoroughly inspected by our Quality Control Team. Every detail including the finish, lamping, dimensions, even down to the packaging and side marks, is reviewed and inspected before leaving our factory.

Every piece is thoroughly inspected to meet our high-quality standards.

electrical and wiring

All of our fixtures adhere to industry standards and are UL approved and CSA listed.

UL approved and CSA listed.

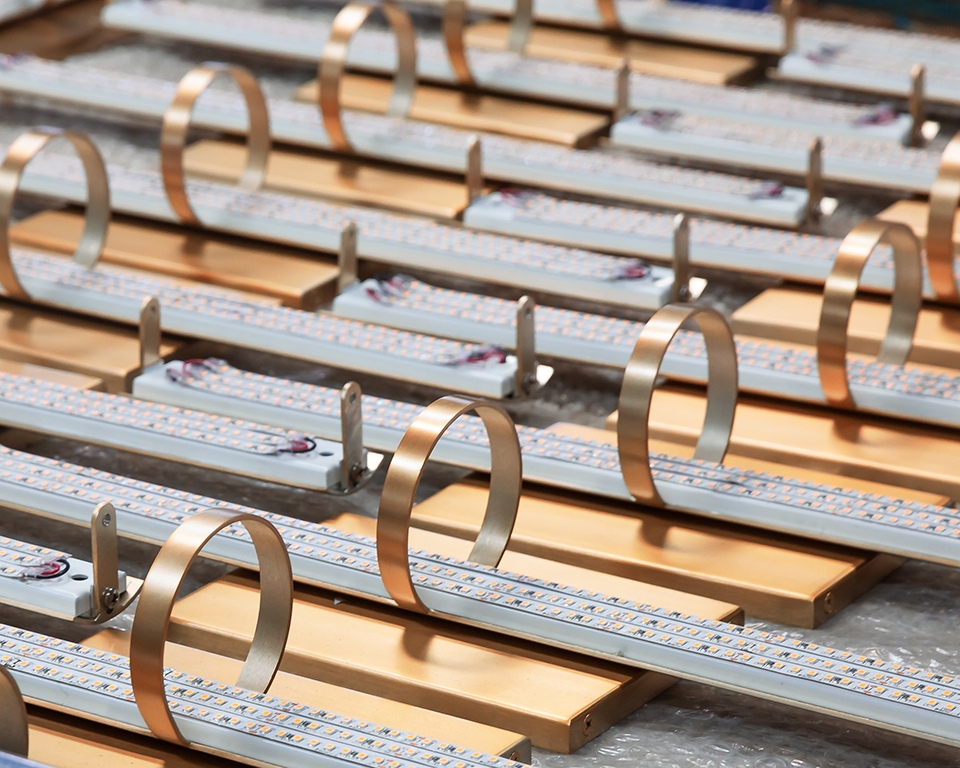

LAMPING SPECIALISTS

Our Engineers and LED specialists have extensive knowledge in various lamping methods, including neon lights, and we will find solutions to the biggest lamping challenges.

Our specialists find solutions to the biggest lamping challenges.

Glass Studio

In 2020, we expanded our domestic capabilities to include our own artisan blown glass studio.

Artisan glass crafted in New York City.

PACKING

All of our fixtures are packed securely to prevent damage during transit, and when required can ship in custom, shock-sensor crates. For easy unpacking and installation, fixtures are packed as completely assembled as possible.

Fixtures are packed in custom crates with shock-sensors.

ENGINEERING

Our in-house engineering team has skill sets ranging from initial concept sketching, AutoCAD, 3D modeling, shop-drawing production, and interpreting designer concepts into CAD produced shop drawings for manufacturing.

In-house engineers interpret design concepts into manufacturable products.

Artisan Glass

In 2020, we expanded our domestic capabilities to include an artisan blown glass studio.

Artisan glass crafted in New York City.

CNC MACHINING

We use modern technology and a state-of-the-art CNC lathe and milling machine to produce metal parts with precision.

CNC lathe and milling machine to produce a variety of metal parts.

METAL CUTTING

Our large-scale metal cutting laser machine can cut large sheets of metal into patterns and shapes, for fixtures and to create templates.

Metal cutting laser machine can cut large sheets of metal into various shapes and patterns.

WELDING

Our certified welders know the art of heating and shaping materials. They have strong technical educations and specialize in fabricating and fusing together materials like brass, steel, stainless steel and aluminum.

Fabricating and fusing together various metals and materials.

POLISHING

We have various polishing machines, hand and automated, for large- and small-scale metalwork.

Capabilities to polish any size piece of metal.

FINISHING

Our in-house artisans are true artists; skilled to apply finishes using multiple finishing techniques. Faux finishes painted by hand to resemble real alabaster, marble or wood.

True artists skilled at applying faux finishes by hand.

SPRAY BOOTH

Our factory houses a state-of-the-art, automobile-scale spray booth for spraying and finishing large-scale fixtures and parts.

State-of-the-art spray booth.

SANDBLASTING

Metal parts are sandblasted to ensure a smooth surface prior to applying painted finishes. Glass and acrylic are sandblasted to create etched and frosted patterns.

Sandblasting to smooth surfaces and create frosted glass and acrylic.

MACHINING

Our factory is vertically integrated with various machines that enhance our capabilities to meet the most challenging designs. Lathe, milling, rolling, drilling, and grinding machines, to name a few.

Various machines that enhance our capabilities.

CUSTOM SHADES

Select from our wide range of standard shade materials or specify your own. We can make custom wire forms of any shape or size.

On-site shade department. Select from our standard materials or specify your own.

LAMPING SPECIALISTS

Our Engineers and LED specialists have extensive knowledge in various lamping methods, including neon lights, and we will find solutions to the biggest lamping challenges.

Our specialists find solutions to the biggest lamping challenges.

electrical and wiring

All of our fixtures adhere to industry standards and are UL approved and CSA listed.

UL approved and CSA listed.

QUALITY CONTROL

Every item is thoroughly inspected by our Quality Control Team. Every detail including the finish, lamping, dimensions, even down to the packaging and side marks, is reviewed and inspected before leaving our factory.

Every piece is thoroughly inspected to meet our high-quality standards.

PACKING

All of our fixtures are packed securely to prevent damage during transit, and when required can ship in custom, shock-sensor crates. For easy unpacking and installation, fixtures are packed as completely assembled as possible.

Fixtures are packed in custom crates with shock-sensors.

FINISHES

We offer a wide selection of painted and plated standard finishes ranging from antique brass to gunmetal.

Need a custom finish? Our in-house artisans will make a finish to fit your needs and budget.

LOCAL & WORLD-WIDE SOURCING

Our purchasing team has long-standing relationships with a network of local and international suppliers to purchase various materials, from both a standards component and on a custom basis.

FINISHES

We offer a wide selection of painted and plated standard finishes ranging from antique brass to gunmetal.

Need a custom finish? Our in-house artisans will make a finish to fit your needs and budget.

LOCAL & WORLD-WIDE SOURCING

Our purchasing team has long-standing relationships with a network of local and international suppliers to purchase various materials, from both a standards component and on a custom basis.

© 2024 HB Lighting, Inc. – All Rights Reserved.